Detailed plans for one of the UK’s largest onshore oil production schemes in recent years have been published.

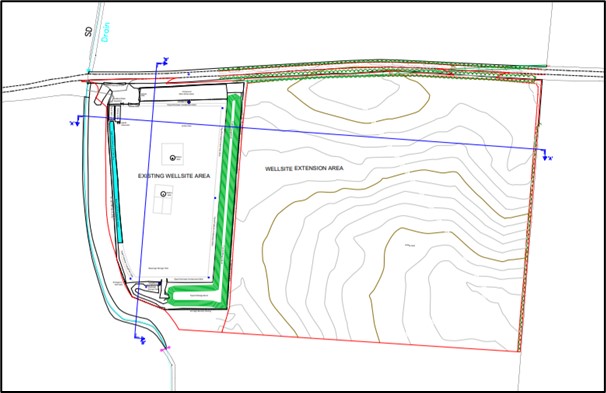

Image: Rathlin Energy

Rathlin Energy is seeking permission to extract oil at the West Newton A site in East Yorkshire for 20 years.

It also proposes to expand the existing two wells to a total of eight. The area of the site would increase by almost four times, from 0.9ha to 3.46ha.

This is the largest application for onshore oil production to go through the planning system in at least eight years.

A similar application, at Horse Hill in Surrey, in 2019, increased the number of wells from two to six and expanded the site size to 2.8ha. A production application for Biscathorpe in Lincolnshire, expected to be decided this autumn, has just one additional well and a site area of 2.4ha. Both required detailed environmental impact assessments (EIAs).

According to the West Newton A application, the expanded site could see 90 weeks of drilling, using a rig up to 55m tall.

It could generate up to 132 vehicle trips per day during its second year.

In production, the site would be able to store up to 490 tonnes of crude oil at any time. This represents 3,600 barrels or enough oil to fill more than 15 of the UK’s largest road tankers. Up to 330 million cubic feet of gas could be burned on site.

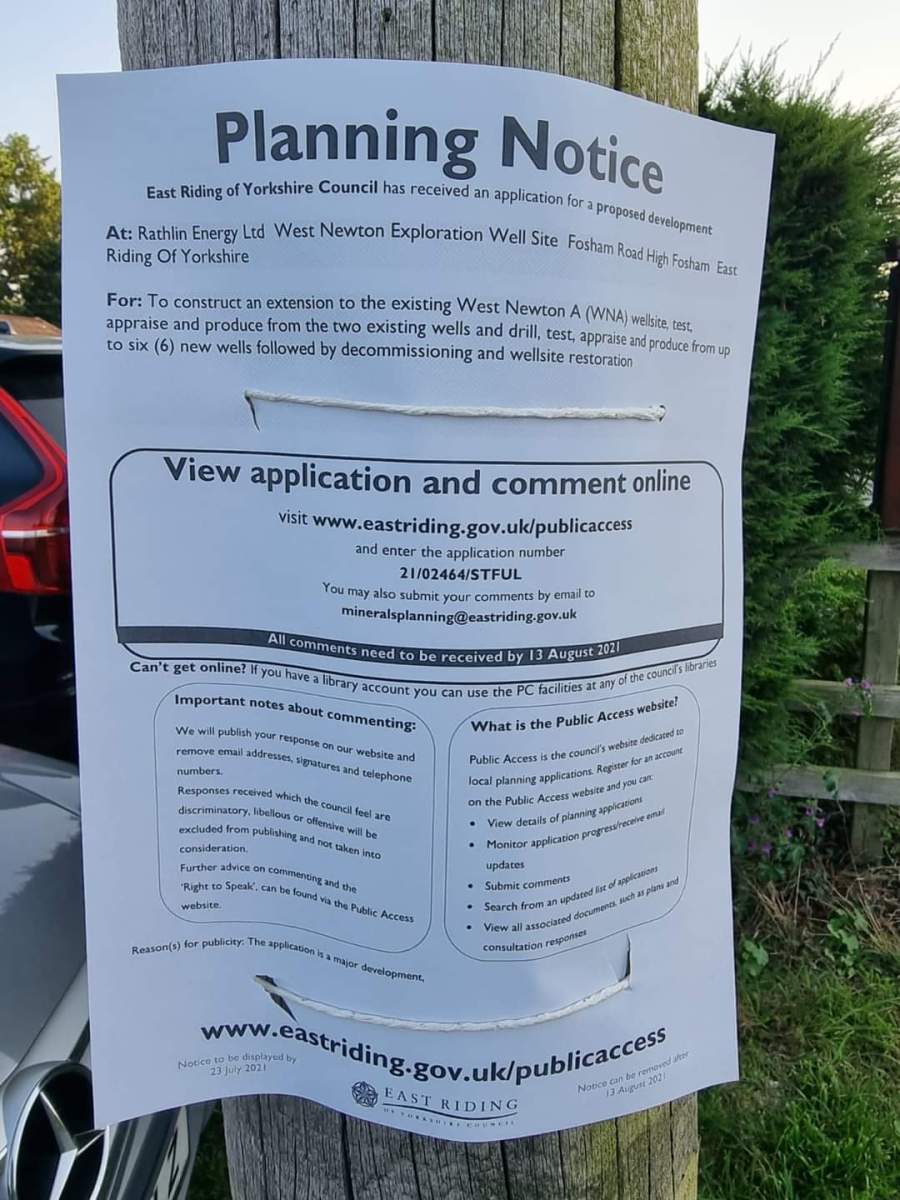

The proposals have already prompted concerns about increased traffic and pollution. Local representatives unsuccessfully called for an EIA to be carried out as part of the application.

Last night, Rathlin Energy said it had responded to a community consultation and reduced the maximum estimated daily lorry movements by more than half during the production phase.

Nearly 60 application documents are now on the planning website for East Riding of Yorkshire Council (application 21/02464/STFUL).

A public consultation is underway until Friday 13 August 2021. The proposal could be decided in the autumn.

West Newton A is 2km from Rathlin Energy’s other oil site, West Newton-B site. The company is planning a further two sites locally (West Newton C and D).

DrillOrDrop will follow the proposal through the planning process and will report on reactions to it. This rest of this article is based largely on information in the company’s planning application.

Source: Rathlin Energy

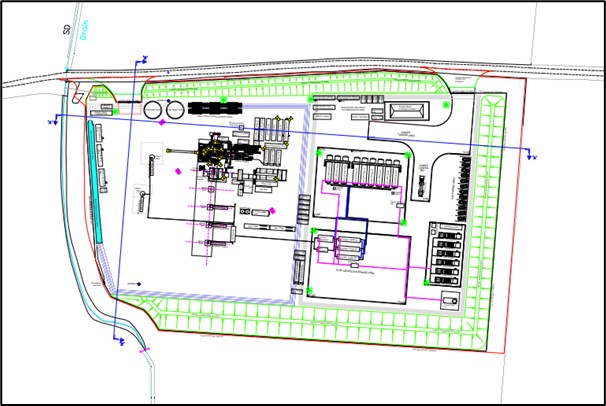

Source: Rathlin Energy

Key details

Application

Reference: 21/02464/STFU

Location

Nearest villages: West Newton (1.1km) and Marton (0.8km)

Nearest home: 625m

Nearest wildlife sites: Lambwath Meadows Site of Scientific Interest (1km) and Lambwath Stream local wildlife site (400m)

Ownership: Rathlin said it had an agreement with the landowner for the existing wellsite and a “variation to allow for wellsite extension is being sought”.

The site

Initial planning permission: January 2013.

Start of site construction work: March 2013

First well drilled: June 2013

Second well drilled: April 2019

Planning extension: In November 2018, East Riding of Yorkshire Council granted an extension of permission for a further three years.

DrillOrDrop reported that Rathlin Energy breached at least 14 conditions of its environment permit for West Newton A in four months in 2015

In its new application, Rathlin Energy said:

“The application site is considered by the Applicant to be the most suitable location from which to extend the existing wellsite, test, appraise and produce from the two existing wells and drill, test, appraise and produce from up to a further six (6) new wells. The application site meets the surface selection criteria and seeks to minimise adverse impact on both environmental and social interests.”

Environmental Impact Assessment

East Riding of Yorkshire Council ruled in January 2021 that the application did not need an EIA. In March 2021, a group of nearly 30 local representatives asked the local government secretary to review the decision. In June 2021, a screening direction from the local government secretary confirmed an EIA was not needed.

Proposed work phases

1. Appraisal testing and workover of existing wells

Operations: Initial appraisal followed by possible wellbore treatments or mechanical lifts. This would include pumping acid into the wells below formation fracturing pressure. Deviated wells could be drilled off the existing wells, WNA-1 and WNA-2.

Duration: Up to 12 months

Working hours: 24 hours per day, seven days a week

Equipment: Workover rig and/or coiled tubing unit, wireline trucks, nitrogen conversion and well test equipment, flares, metering, tanks

HGV (heavy goods vehicle) movements in and out: 20 per day for mobilisation/demobilisation; 5 per day for appraisal testing and workover

Staff: 25

Security staff: 12

Lighting: 1 portable lighting tower

Extracted waste: Formation water, spent acid, well suspension brines. Flaring of gas would be limited to 330mmscf (million standard cubic feet) except in an emergency.

2a Wellsite extension construction

Operations: Removal of topsoil, installation of surface water management system, construction of drilling cellars, addition of stone and reinforced concrete, security fencing and access gates.

Duration: Up to 14 weeks

Working hours: 7am-7pm, Monday-Saturday

HGV movements in and out: 10 per day for mobilisation/demobilisation; 30 per day for pad construction

Staff: 12

Security staff: 12

2b Conductor installation

Operations: Installation of conductor casing for each new well

Equipment: Drilling rig (up to 15m)

Duration: 28 days per well plus eight days for mobilisation/demobilisation

Working hours: Conductor drilling 24 hours per day, seven days a week

HGV movements in and out: 5 per day for mobilisation/demobilisation; 3 per day for installation

Lighting: Mobile lighting towers may be used for early morning and early evening work

Extracted waste: Drill cuttings, drilling muds, excess cement

3 Drilling

Operations: Mobilisation of drilling rig (up to 55m) and other equipment; drilling six main wellbores; temporary storage of drilling mud and rock cuttings; installation of lighting; delivery of fuels, equipment, materials, chemicals, casing and tubing. Sidetracks of the main wellbores may also be needed.

Duration: 15 weeks per well, four weeks for each mobilisation/demobilisation

Working hours: Drilling 24 hours per day, seven days a week

HGV movements in and out: 25 per day for mobilisation/demobilisation

Lighting: 4 lighting towers with lights on the rig floor, mud tanks and shakers, derrick and cabins

Extractive waste: Drill cuttings, drilling muds, excess cement

Target formation: 2 conventional reservoirs in Permian age carbonates at depths of 1,600m-2,000m. The wells would not drill into shale and they would not target unconventional resources, the application added.

4 Well treatment and clean up

Operations: Perforation of the casing, acid treatment, gas or mechanical lift or use of subsurface pump to flow hydrocarbons

Duration: 4 weeks per mobilisation/demobilisation; four weeks per well for treatment and clean up

Working hours: 24 hours per day, seven days a week

HGV movements in and out: 20 per day for mobilisation/demobilisation; 5 per day for treatment operations

Lighting: Similar to production phase

Extractive waste: formation water, spent acid, well suspension brine

5 Well testing

Operations: Testing to establish gas and oil composition, flow rates and pressures. Gas will be burned in a flare and oil transported off site.

Duration: 1-2 years

Working hours: 24 hours per day, seven days a week

HGV movements in and out: 5 per day

Lighting: 4 fixed pole mounted lighting (6m)

Extractive waste: Formation water, well suspension brines, gas

6 Production

Operations: Reconfiguration of the wellsite and installation of tanks (up to 8m), incinerator and vent stack (up to 15m). Storage accommodates up to 490 tonnes (3,600 barrels) of crude at one time. The application does not include processing or export of methane gas, which would be incinerated or used to power wellsite generators. If the incineration budget of 330mmscf were exceeded, Rathlin said it would submit a separate application.

Duration: 15-20 years

Working hours: 24 hours per day, seven days a week

HGV movements in and out: 20 per day for mobilisation/demobilisation; 10 per day for production and maintenance

Lorry movements: Rathlin Energy said it estimated up to 25 daily tanker visits to remove oil from the site but after local feedback it had reduced the maximum to 10 each day

Lighting: 4 fixed pole mounted lighting (6m)

Extractive waste: Formation water and well suspension brines

7 Well workovers, routine maintenance and repairs

Operations: Use of a workover rig (35m) or crane to change pumps or production tubing, re-perforating, acid treatment or cleaning

Working hours: 24 hours per day, seven days a week

Duration: Depends on work required

HGV movements in and out: 10 per day for mobilisation/demobilisation; number for workovers depends on operations

Lighting: 4 lighting towers with lights on the rig floor, mud tanks and shakers, derrick and cabins

Extractive waste: Drill cuttings, drilling muds, excess cement, formation water, spent acid, well suspension brines

8 Decommissioning

Operations: 35m workover rig, generators, pumps and tanks to set cement plugs into the well. The well casing is cut to 1.5m below ground level and a steel plate welded over the casing.

Duration: Mobilisation/demobilisation 4 weeks; plugging and abandonment 3 weeks per well; removal of surface production equipment 8 weeks

HGV movements in and out: 20 per day for mobilisation/demobilisation; 10 per day for removal of surface equipment; 5 per day for plugging wells

Lighting: 4 lighting towers with lights on the rig floor, mud tanks and shakers, derrick and cabins

Extractive waste: excess cement, formation water, well suspension brines

9 Restoration and aftercare

Operations: Dismantling of drilling cellars, removal of surface aggregates and site membrane, soil replaced, removal of security fencing, reinstatement of hedgerows and trees

Duration: 8 weeks for restoration, 5 years for aftercare

Working hours: 7am-7pm Monday-Saturday

HGV movements in and out: 10 per day for mobilisation/demobilisation; 30 per day for earthwork restoration

Lighting: 1 portable lighting tower for early morning and dusk

Staff: 6

Security staff: 12

Key issues

Traffic

During the drilling phase, the development was expected to generate up to 122 daily vehicle trips (61 in and 61 out), Rathlin said. 38 daily vehicle trips had previously been allowed during the exploration phase, it said.

“it would be reasonable to assume that of the maximum of 122 daily vehicle trips associated with the proposed production phase for the wellsite, there would only be 84 additional to the exploratory testing phase.”

The company said HGV trips would be “spread out across the operating hours” and most staff journeys would be outside peak hours.

It added that the proposed route from the A165, via Langthorpe Road and Piper’s Lane, was suitable for HGVs and there were no road safety concerns. The impact on the local highway network was “not expected to be severe”, Rathlin said.

Landscape

Rathlin said the 55m drilling rig would be a prominent feature and would “detract from the rural character of the landscape”. But it said the degree of change would be lessened by the Withernwick Wind Farm turbines. The company said:

“the adverse effects on the rural character of the landscape (LCA19D) would be temporary and reversible, lasting a maximum of 24 months.”

The wellsite would be prominent when viewed from homes in High Fosham and Marton but the views would “not be so unpleasant, or overwhelming and oppressive as to make the properties unattractive places to live”, Rathlin said.

During production, the impact on the landscape would be lower than during the drilling phase and the impacts minimal, the company added.

Security fencing, cameras, lighting and access gates “may have an urbanising effect on rural views” from Fosham Road and nearby public footpaths. But the company said these effects would “be very localised and would affect a very small number of people, who are already exposed to views of the existing wellsite”.

To reduce the site’s impact, Rathlin said drilling at West Newton A would not coincide with drilling at nearby West Newton B. The outer slopes of the site’s perimeter mounds would be planted with native trees and shrubs, the company added.

Noise

Rathlin said there would be “a very small temporary increase in traffic noise” in Sproatley village and on Pasture Lane. This was likely to be minimal, the company said, and was “not considered a significant impact”.

The drilling and rig and other plant would “minimise noise levels to the lowest reasonably practical level”, it said. Noise from the site would meet planning guidance and would not “cause a significant adverse impact”, it added.

Air quality

Rathlin said the main sources of pollutants would be diesel fuels from vehicles and equipment and the burning of gas.

The company said these pollutants were considered “largely insignificant” and “no significant threat” to people living in neighbouring homes or to nearby wildlife sites.

The risk from dust would be “negligible”, it added.

Greenhouse gas emissions and climate change

Rathlin said the application provided an opportunity for “local customers to be supplied with an indigenous hydrocarbon of a lower carbon footprint than imports from the point of extraction”.

It said West Newton A oil would have a lower carbon intensity than imports and the site was “ideally placed to support a transition to a low carbon future”.

On greenhouse gas emissions, the company said there would be increases locally and for the fuel supply sector. It said all energy resources, including wind and solar, resulted in increased emissions. But it added:

“Based on an assessment of worst-case operation, it is considered that Project lifetime greenhouse gas releases are largely insignificant in relation to the UK’s current inventory and future budgets.”

Need for the development

Rathlin Energy said there was a continued risk of gaps in the supply of hydrocarbons in the UK.

“should the development be permitted, it will contribute to the reduction in the supply gap”.

What the application says about other impacts

Human health: “Not likely to be significant”

Lighting: Plans complied with guidance

Groundwater: Risks would be reduced to very low or none

Wildlife: Not likely to result in “any more than a very localised exclusion of foraging or commuting bats”

Heritage and archaeology: Impact on setting and significance of nearby heritage assets would be “negligible and temporary”

Economy: Generate employment and boost the local economy through procurement and supporting agricultural diversification, as well as paying business rates

Waste: No significant effects

Recreation: The application identified three footpaths within 500m of the site The nearest is next to the northeast corner. Rathlin concluded “no significant impact is anticipated on any users of the rights of way”.

Planning policy

Rathlin Energy says the application complied with the following:

- East Riding Local Strategy Document:

- presumption in favour of sustainable development (policy S1)

- supporting development in villages and the countryside (policy S4)

- supporting growth and diversification of the East Riding economy (policy EC1)

- enhancing sustainable transport (policy EC4)

- integrating high quality design (policy ENV1)

- promoting a high quality landscape (policy ENV2)

- valuing heritage (policy ENV3)

- conserving and enhancing biodiversity and geodiversity (policy ENV4)

- strengthening green infrastructure (policy ENV5)

- managing environmental hazards (policy ENV6)

- East Riding Local Plan Allocations Document

- Joint Minerals Local Plan

- Exploration boreholes (policy EM2)

- Appraisal boreholes (policy EM3)

- Oil and gas production and distribution (policy EM4)

- Impacts of mineral development (policy DM1)

- Protecting residential amenity (policy DM2)

- Restoration and aftercare (policy DM3)

- Best and most versatile agricultural land (policy DM4)

- Public rights of way (policy DM5)

- Transport (policy DM6)

- National policy statement on energy

- National Planning Policy Framework

- Sustainable development

- Economy

- Health and safe communities

- Transport

- Climate change, flooding and coastal change

- Pollution

- Land stability

- Historic environment

- Nature conservation

- Minerals

- Planning Practice Guidance on air quality, climate change, conserving and enhancing historic environment, determining a planning application, flood risk and coastal change, land stability, light pollution, minerals, natural environment, noise, travel

- Climate Change Committee statement on onshore petroleum (31 March 2021)

Updated 23/7/2021 to add end date for public consultation

Categories: Regulation, slider

Why the concern about the height of a drilling rig?

This is a temporary structure, much like a crane upon a building site, or on a farm whilst new buildings are constructed.

Hardly in the same category as a wind turbine, that once erected is there continuously until decommissioned, seen for miles around and emitting continuous noise. If the wind blows.

Interesting and valid point Martin, especially when you compare the 55 metre temporary rig height against the 13 permanent turbines with a tower height of 87 metres and the blade tip height of 113.5 metres, on the Withernwick wind farm that is close by and within clear sight of WNA.

Looks a lot neater than a lot of the farm Infrastructure in the UK, and much less visible.The environmental impact looks neglible, especially as its probably a gas development with possible liquids (condensate).

Once developed should also reduce the UK reliance of imported hydrocarbons and support the viability of the Humber Hydrogen/Low Carbon Hub.

Once depeleted, the field could also be used for carbon capture/storage as well presumably.

“Rathlin Energy said there was a continued risk of gaps in the supply of hydrocarbons in the UK.

“should the development be permitted, it will contribute to the reduction in the supply gap”

This is at some risk of this being opinion peddled as fact.

There were serious risks of gaps in the supply of hydrocarbons in the UK during WW2, the Cold War and the Suez Crisis.

Indeed it is probable that onshore production in Eakring was crucial at the time of the Battle of Britain.

I’d be interested to read a balanced account of the supply of hydrocarbons in the UK, in order to consider the case for the postulated “supply gap”.

Robin Grayson MSc FGS

Yes, and in WW2, drillers came over from USA to help find oil when desperately needed, and they did. Wonder if anyone complained then?

Whilst any country is importing a commodity it usually means they use more than they produce in said country. Thus there is always a risk of a supply gap if those imports are curtailed. If anyone is interested they can trawl back through history and find how often global events impinge upon oil and gas exports. The answer is quite often, which is why wars are constantly fought to control supply lines.

There. Pretty balanced, and not too difficult.

Seems the Greens have joined Labour in calling for less reliance on overseas production as UK carbon footprint overseas should not be ignored. Lib Dems have yet to catch on?

This is a planning Application for Production. so why is more than Half the Objections on how its Built you don’t see that with other applications If they were building houses on the site would they be objecting to the height of the scaffolding & how high the crane was to lift the trusses. no it never gets a mention. this is objecting for the sake of objecting.