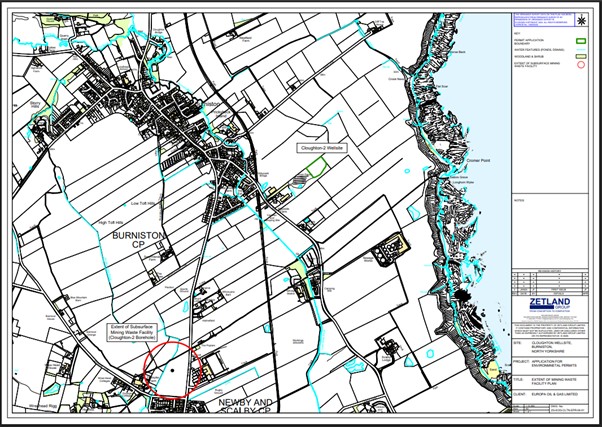

People are invited to comment on the environmental impacts of gas exploration, including lower-volume fracking, at Burniston in North Yorkshire.

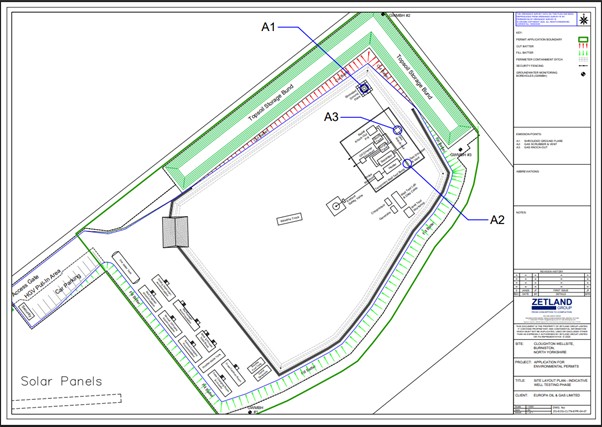

Source: Europa Oil & Gas permit applications

The company behind the scheme, Europa Oil & Gas, has applied for environmental permits, among the several consents it needs before work can go ahead.

Europa wants to drill and test a well on the edge of Burniston and carry out a proppant squeeze, a form of lower-volume hydraulic fracturing, which is not prevented by the moratorium on fracking in England.

A planning application is currently being considered by officials at North Yorkshire Council.

The Environment Agency, which will decide the permit applications, has opened a public consultation, which runs until 13 August 2025. Link here to application and details on how to comment

Since this article was published, the deadline for comments on the environmental permit has been extended to Friday 19 September 2025. DrillOrDrop article

The permits are for a mining waste operation, mining waste facility and a groundwater discharge activity. If approved, the permits would allow Europa to burn waste gas in a flare, dispose of waste from drilling the well and allow fluid from the proppant squeeze to remain underground.

Proppant squeeze

The proppant squeeze is described in the applications as a hydraulic fracture stimulation or treatment.

Europa said it expects to carry out several proppant squeeze operations. Each one would pump 300-500m3 of gelled fluid and 12.5 tonnes of proppant, resin-coated ceramic beads into the target rocks surrounding the well.

The maximum total volume injected would be 1,500m3, the application said.

The applications also said:

- The proppant squeeze was designed to create new fractures in the rocks around the wellbore to improve the flow of gas from target formations

- It would target sandstone formations around 2,000m below ground level and up to 1.6km from the wellsite

- The fluid and liquid for each proppant squeeze would be injected at a surface pressure of 9,000 psi (pounds per square inch) for less than one hour.

- The pressure would exceed the fracture gradient – it would create fractures in rocks

- The maximum rate of injection litres per second has yet to be decided

- The fractures would spread 100m horizontally either side of the borehole and 20-60m vertically either side.

- Up to 70% of the proppant fluid would remain in the formation, about 750m3-1,050m3

- Europa said allowing the fluid to remain underground is considered the best available technique (BAT)

- By volume, the proportion of hazardous waste remaining in the formation would be 1.04%

- A diagnostic fracture injection test, using 15m3 of fluid, may be carried out before the proppant squeezes to determine the breakdown pressure, propagation pressure and carrier fluid leak-off rate

Source: Europa Oil & Gas permit applications

Extended well test and flaring

Europa said in the applications it would carry out multiple extended well tests on the primary target (Carboniferous sandstones) and the secondary targets (Permian brotherton limestone and the Kirkham abbey formations).

It said:

“Information obtained from a specific zone is not likely to provide details and information on another.”

Source: Europa Oil & Gas permit applications

The applications also said:

- The extended well tests would produce waste gas, along with potentially crude oil, condensate and formation water

- Gas would be burned in a PW Well Services shrouded ground flare with a maximum disposal capacity of 6.5MMscfd (million standard cubic feet per day)

- The application acknowledged that an enclosed flare would have “the best combustion efficiency and reduced noise and visible flame”.

- But it said a shrouded flare could “accommodate variable and unpredictable flow”

- Gas incineration would be more than 10 tonnes a day

- The well clean up and extended well test could burn a total of 68.5MMscf or 1,106 tonnes

- The test phase, scheduled to take 17 weeks, was too short to generate electricity from the gas or export it to the grid

- Any crude oil, condensate and formation water would be separated and transported off the site for refining or treatment

DrillOrDrop will report on the permit applications process

Categories: Regulation, slider