The UK’s second largest onshore oil production site has published proposals to increase its footprint by about a third and drill two new wells.

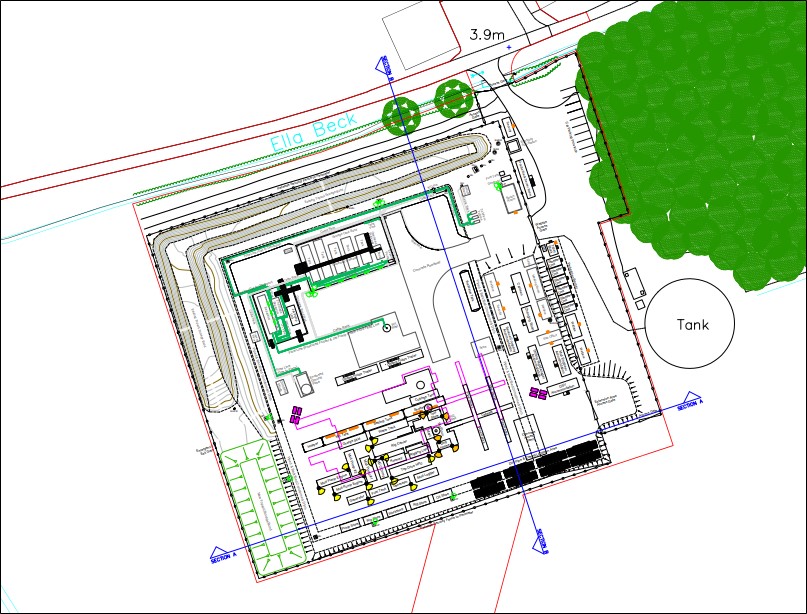

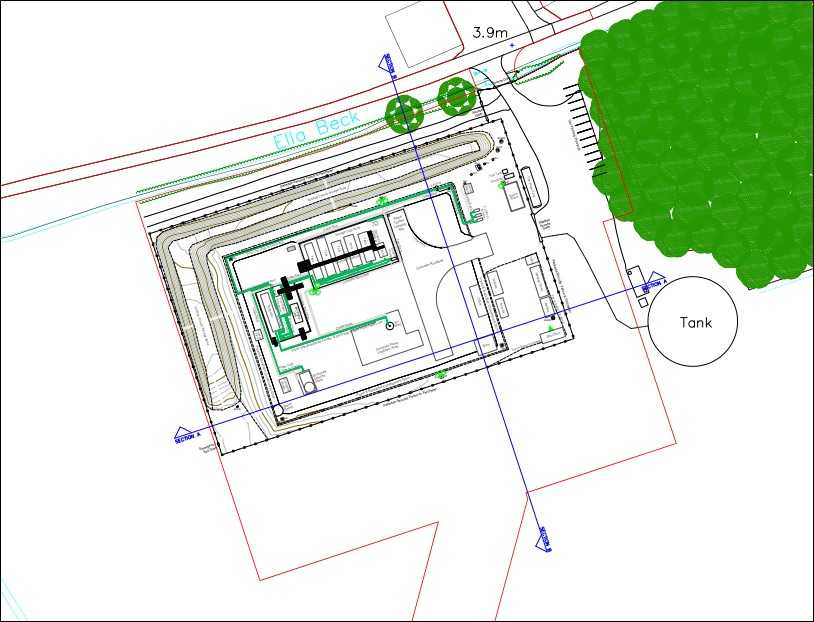

Source: Planning application to North Lincolnshire Council

A planning application for the Wressle site in North Lincolnshire, published today, also seeks permission for long-term production, new processing equipment and an underground pipeline.

The site operator, Egdon Resources, has been producing oil from the Wressle-1 well since July 2022. In 2023, Wressle accounted for about 4% of UK onshore oil production, behind Wytch Farm (76%).

Egdon now wants to drill two new wells, to be called Wressle-2 (W2) and Wressle-3 (W3), to target both oil and gas from the Ashover Grit and Penistone Flags rock formations.

The company has previously estimated that the Wressle field has more than 1.7m barrels of oil and 3.78 billion standard cubic feet of gas.

The application said:

“By enabling the production of indigenous oil and gas reserves, it will help to reduce the need for imports into the UK, thereby reducing associated production and transport greenhouse gas emissions when compared to sourcing the fossil fuels from other countries.”

It said the new plans would “not result in any notable adverse environmental or amenity impacts”.

They would, it said, “deliver modest but positive long-term economic and social impacts for the local community”.

A consultation on the plans by North Lincolnshire Council continues until 25 April 2024.

Details

The planning application comprises more than 40 documents, including a 64-page planning statement, by the consultancy, Aecom.

The proposals include:

- Extension of the existing site by an area of 0.67ha, increasing the current site of 1.85ha by 36%.

- Construction of three well cellars

- Back-to-back drilling of two lateral boreholes – the additional cellar may be used to drill a future water injection well

- Upgraded production facilities, including fluid storage tanks, separator system, surface pump, associated bunds

- New gas processing equipment

- 600m underground gas pipeline to link Wressle to the national gas grid

The application said it would not use high volume hydraulic fracturing.

But it does refer to a proppant squeeze, a small-scale hydraulic fracturing technique used when the flow of hydrocarbons is restricted by reduced permeability of rock formations.

Proppant squeeze is allowed under the current moratorium on fracking in England. It does require a hydraulic fracturing plan that must be approved by the Environment Agency and North Sea Transition Authority. The process was used on the Wressle-1 well.

Proposed work phases

Phase 1 site construction

Operations: develop wellsite extension with new fencing, drainage, and containment system; install three new well cellars within 10-20m of current Wressle-1 cellar.

Duration: Eight weeks

Operating hours: 7am-7pm, Monday-Saturdays

Average HGVs per day: 6

Total HGV numbers: 238

Employment: 7 on site, 4 off site

Phase 2 drilling

Operations: Drill and complete Wressle-2 (W2) and Wressle-3 (W3) wells in southerly/southwesterly directions using a 42m rig

Duration: 21 weeks, allowing for rig to be demobilised between well drilling if necessary

Operating hours: Mobilisation/demobilisation: 7am-7pm, Monday-Saturdays; drilling W2 and W3: 24 hours/7 days a week; completion of wells: 7am-7pm 7 days a week

Average HGVs per day: drilling and completion 5

Total HGV numbers: drilling and completion 536

Employment: 8 on site, 6 off site

Phase 3 production testing and proppant squeeze

Operations: Test production from W2 and W3 wells; proppant squeeze followed by further test production of W2 and W3. The proppant squeeze would use about 150m3 of water, salt and 20-30 tonnes of ceramic bead proppant with what was described as “several minor chemical additives, all of which are widely used in the UK”.

Duration: Initial test 9 weeks; proppant squeeze 3 weeks; second test 5 weeks

Operating hours: Initial test 24-hours, 7 days a week; proppant squeeze 7am-7pm, Monday-Saturday; test production 24 hours, 7 days a week

Average HGVs per day: Initial test production 3; proppant squeeze 4; second test production 3

Total HGV numbers: Initial test production 128; proppant squeeze 61; second test production 58

Employment: 8 on site, 6 off site

Phase 4 production

Operations: Site civils works, including new storage tank and surface pump bunds, extension of internal road, installation of plinths for gas processing equipment; installation of extra production facilities, including four storage tanks, additional separator system and up to two surface pump systems; construct underground gas pipeline; production of oil and gas; export of gas to network via 600m pipeline to connection south west of site.

Duration: site civils works 8 weeks; enhanced production installation 14 weeks; gas to grid 7 weeks

Operating hours: site civils work7am-7pm, Monday-Saturday; installation of enhanced production facilities: 7am-7pm, 7 days a week; production:24 hours, 7 days a week; gas to grid connection 7am-7pm, Monday-Saturday

Average HGVs per day: Site civils work 3; installation of enhanced production 1; production 5; gas to grid 2

Total HGV numbers: Site civils work 88; installation of enhanced production 27; gas to grid 60

Employment: 21 on site, 6 off site

Phase 5 decommissioning and restoration

Operations: Plug and decommission wells; restore site to farmland

Duration: 12 weeks

Operating hours: 7am-7pm, Monday-Saturday

Average HGVs per day: Well decommissioning and site restoration 6

Total HGV numbers: Well decommissioning and site restoration 348

Employment: 21 on site, 5 off site

Key facts

Address: Wressle-1, Lodge Farm, Clapp Gate, Appleby DN15 0DB

Grid reference: SE 96801 11122

Location: 1.6km north west of village of Wressle

Application reference: PA/2024/275

Application link: https://apps.northlincs.gov.uk/application/pa-2024-275

Licence area: The Wressle site is in PEDL182 and field extends across PEDL180. Egdon, through its parent company Heyco, has a 30% stake and is the operator of both licences.

Current site size: 1.85ha including access track

Proposed extension: 0.67ha

Nearest homes to site: Decoy Farm (460m), Decoy Cottage (460m), North Cottage (500m)

Nearest homes to proposed pipeline: Broughton Cottages (290m)

Local or national landscape designations: None

Formal ecological designations covering the site: None

Nearest designated wildlife areas: Broughton Far Wood SSI (600m from wellsite) Broughton Alder Wood (660m from proposed pipeline); six nature reserves within 1km of the site

Flooding: Flood Zone 1 (very low risk)

Nearest watercourse: Ella Beck borders the wellsite and access track

Drinking water: not in a source protection zone or drinking water safeguard zones. It is in a drinking water protected area and a nitrate vulnerable zone

Scheduled monuments: Thornholme Augustinian Priory 1.3km from site. 10 listed buildings within 2km

Planning policy: The application claims that it accords with the North Lincolnshire Local Plan, North Lincolnshire Core Strategy and the Appleby Parish Council Neighbourhood Plan. It also says it accords with Nationally Planning Policy Framework and planning practice guidance and government on energy and climate change.

The planning statement said:

“Both local and national policy recognise the need for indigenous hydrocarbon production to ensure the security of energy supply and reduce national demand for imports, as well as the local economic benefits of hydrocarbon production.”

DrillOrDrop will report on reaction to the planning application and the passage of the proposals through the planning system

DrillOrDrop has closed the comments section on this and future articles. We are doing this because of the risk of liability for copyright infringement in comments. We still want to hear about your reaction to DrillOrDrop articles. You can contact us by clicking here.

Categories: Regulation, slider